Predictive Maintenance

HOW

staying grounded lifts up your business.

staying grounded

lifts up your business.

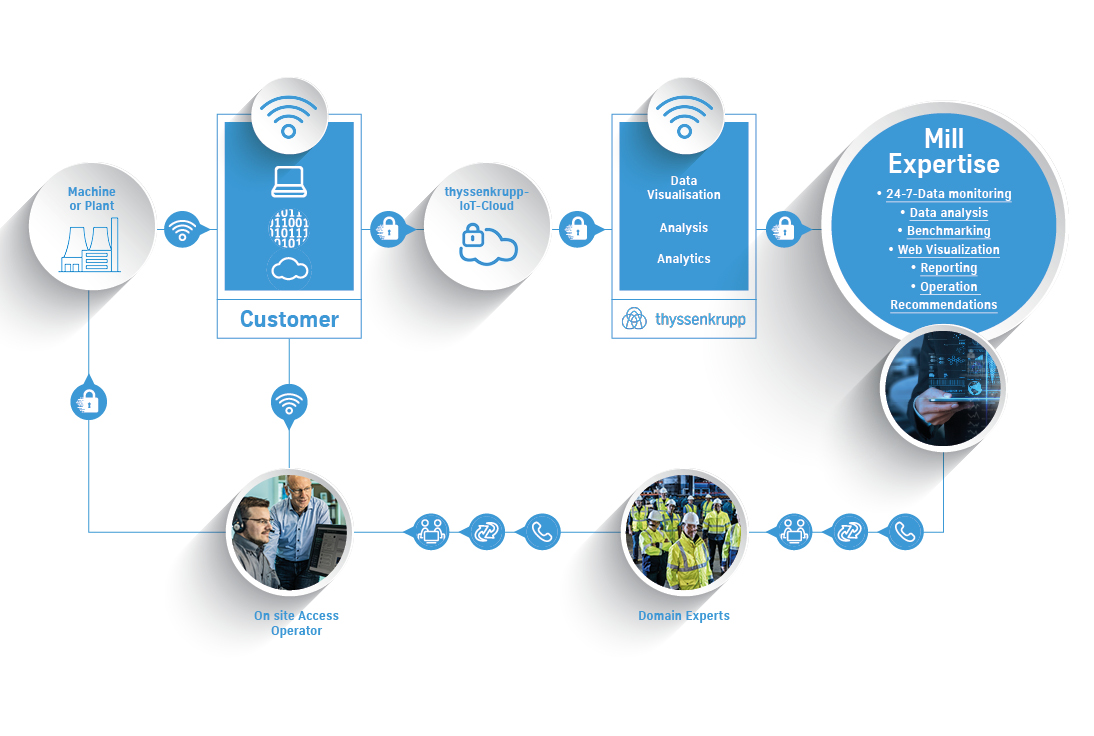

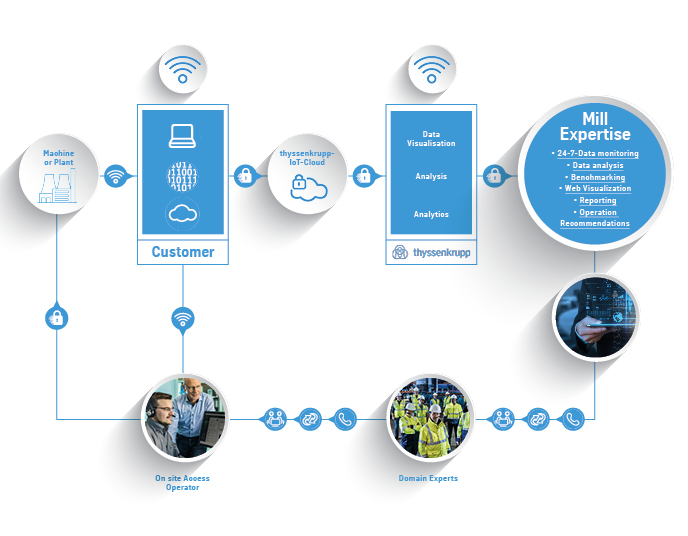

Prediction and provision

Expert Reporting

Digitization as a

service

Predictive Maintenance is the analysis of process data for early detection of

abnormal machine behavior, wear and malfunctions before critical problems

occur. We monitor your machine and equipment operating conditions over

long periods of time. Based on our many years of experience, we

recommend a tailored maintenance schedule. We determine the optimal

inventory of spare parts and anticipate future needs.

Due to our decades of expertise in cement plant engineering, we are able to

evaluate and define a „normal“ or faulty behavior of a machine. For our

customers, we create the greatest possible transparency about the status

and condition of their plants, detect faults at an early stage and alert the

operator immediately. Costs for maintenance and service can be reduced by

timely and proactive maintenance before critical and costly damage occurs.

Our Predictive Maintenance solutions expand your cement plant’s lifecycle

by providing the best possible care for each of your machines.

Predictive Maintenance

Detect and alert wear & failures early on

Recommend optimal schedule for

maintenance & repairs

Plant availability, safety

Avoid unplanned

downtimes

Benefits

01.

02.

03.

04.

Drone Inspection

Service in lofty heights

Benefits

01.

02.

03.

04.

News

Smarten up!

Our Experts

Our other solutions

thyssenkrupp Industrial Solutions

thyssenkrupp © 2023