Performance Optimization

HOW

to grow your business by growing greener.

to grow your business

by growing greener.

Performance meets sustainability

To us, performance and sustainability go hand in hand: We use

data analytics and machine learning to identify your cement

plant’s strong and weak points to make impactful changes that

increase your plant’s performance noticeably without increasing

emissions.

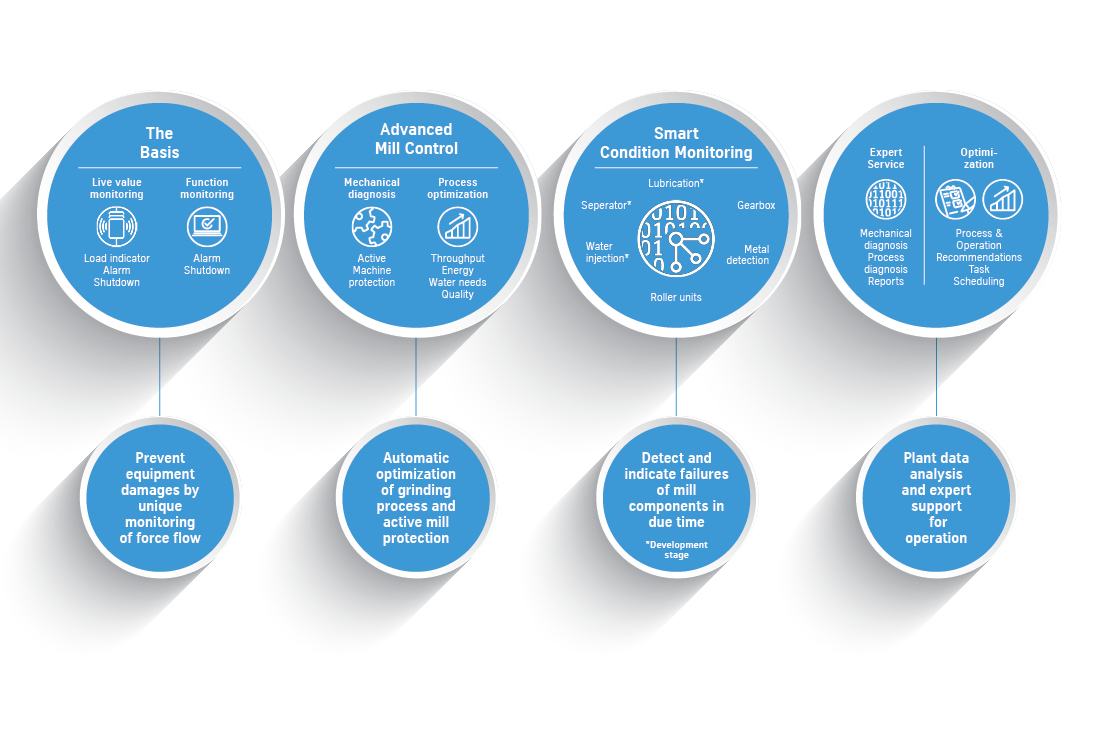

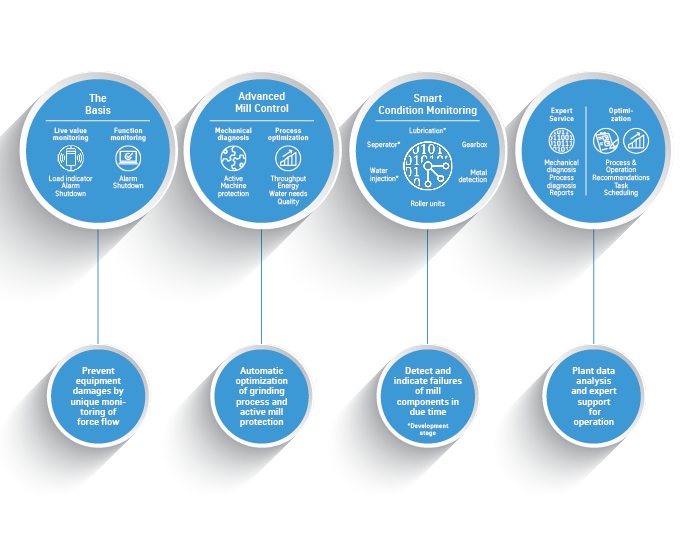

Machine Protection System

Stay in control with automation

Our Machine Protection System is an automated system developed to

prevent equipment damages and malfunctions by unique monitoring and

evaluation of force flow. Its’ primary aim is the observance of load figures,

based on the constructional design, during operation. Certain load values

are monitored by special sensors and analyzed. In case of detecting

overstepping of these load values a noticeable warning is generated.

This way critical loads in your mill over a certain duration are avoided as well as

malfunction and machinery damages – which in turn saves energy and

material resources. With a standardized communication interface, all data can

be analyzed further by domain experts. Recommendations can be created and

maintenance intervals planned.

This way critical loads in your mill over a certain duration are avoided as well as malfunction and machinery damages – which in turn saves energy and material resources. With a standardized communication interface, all data can be analyzed further by domain experts. Recommendations can be created and maintenance intervals planned.

Performance Optimization

Optimize operation with realtime proactive & predictive control

AI algorithms continuously learn from new data & adapt to new conditions

Improve throughput, quality &

efficiency (energy, resources)

Reduce operating costs

Benefits

State of the art Data Analytics and Machine Learning methods

help you identify key performance indicators and information on

how to adjust them to achieve performance optimization of your

cement plant. Once identified and adjusted our Machine

Protection Systems support your production to work within the

optimal parameters: Reducing downtime, energy expenditure and

emissions.

01.

Precise monitoring of critical

mechanical loads

02.

Analysis, monitoring and

evaluation

03.

Fast signal processing

04.

Predictive maintenance strategy

Success Story

Machine Protection System

The development of our Machine Protection System (MPS) started in 2000

with thyssenkrupp’s vertical roller mills Quadropol. The system’s primary aim

is to monitor load figures, based on the constructional design, during

operation. Sensitive load values are monitored by sensors and analyzed.

Since the year 2010 every delivered vertical roller mill has been equipped

with a MPS by default. As our MPS has proven its’ reliability at the vertical

roller mill, it now has been transferred to the high-pressure grinding rolls

POLYCOM. Meanwhile, the development for our long-term goal is at full

speed: To make Machine Protection Systems available for all types of

machinery relevant to cement production.

Advanced Machine Control

Plant operation made easy

As plant operator you know your machines best. Our Advanced Machine

Controller (AMC) continuously adjusts the control parameters according to

the selected targets according to your production’s individual requirements.

In contrast to manual operation, the controller prevents the system from

being overloaded and leads to an improved mill operation. In addition, the

operator’s workload is significantly reduced and he is free for other tasks.

Benefits

The thyssenkrupp service team is always in a position to detect and rectify faults at

short notice through the analysis of our customers plant’s operating and process

data: To stabilize grinding levels, to optimize operation automatically and to

oncrease efficiency.

01.

Self-learning plant

performance optimization:

02.

Meet defined targets

03.

Meet emission regulations

04.

Support operating staff

News

Smarten up!

Our polysius® digital solutions offer easy to implement solutions to either make parts of your

cement production smarter and more sustainable or go all the way and transform your entire

plant to meet today’s regulations and remain competitive in the future. Which approach is

most suitable for your cement plant?

Our Experts

Our other solutions

thyssenkrupp Industrial Solutions

thyssenkrupp © 2023